Photoinitiator (PI) is a key component of photocurable materials, which plays a decisive role in the photocuring speed of photocurable materials. A photoinitiator is a substance that can absorb radiation energy, undergo photochemical changes after excitation, and produce active intermediates (free radicals or cations) with the ability to initiate polymerization. Photoinitiators can be divided into ultraviolet initiators (absorbing ultraviolet 250 ~ 420nm) and visible light initiators (absorbing visible light 400 ~ 700nm) because of the difference in attracting radiation energy. Photoinitiators can be divided into two categories: free radical photoinitiators and cationic photoinitiators because of the different active intermediates produced. Free radical photoinitiators can be divided into two types: cracking photoinitiators and hydrogen robbing photoinitiators because of their different mechanisms of producing free radicals. At present, the main technology of photocuring is ultraviolet curing, and the photoinitiator used is ultraviolet initiator. Due to its sensitivity to daylight and general lighting sources, visible initiators are limited in production and use, and are only applied in a few fields such as dentistry and printing plate making. China's photoinitiator research and development and production began in the 1970s, when the main varieties of benzoin ether photoinitiators, began industrial production in the 1990s, and entered the rapid development stage. Since 2000, China's photoinitiator production and export jumped to the world's first, becoming the world's largest producer and exporter of photoinitiators. With the development of light curing technology, the application field of light curing products continues to expand, and the research and development and production of photoinitiators have also made great progress, mainly towards the direction of low odor, low migration, good solubility and high initiation efficiency. Therefore, new photoinitiators such as macromolecular photoinitiators, macromolecular co-initiators, polymerizable photoinitiators, free radical-cationic hybrid photoinitiators have appeared.

Photoinitiator 819, is an acylphosphine oxide photoinitiator, chemical name phenyl bis (2, 4, 6-trimethylbenzoyl) phosphine oxide, Chinese alias photoinitiator 819; Photoinitiator XBPO; Photoinitiator XBPO alias potoinitiator XBPO, CAS number: 162881-26-7, molecular formula C26H27O3P, molecular weight 418.46500, PSA 61.02000, LogP 6.20620, density 1.17g /cm3, melting point 131-135ºC, boiling point 590ºC at 760 mmHg, flash point 310.6ºC, Refractive index 1.588, vapor pressure 6.78E-14mmHg at 25 ºC.

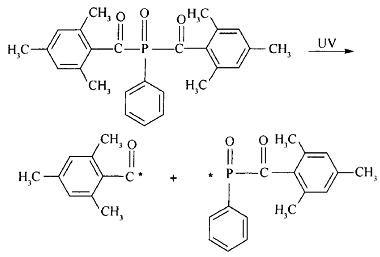

[Mechanism] [4]

[3][4]

Acylphosphine oxides such as photoinitiator 819, as a new type of photoinitiator, have been widely used in coatings, inks, adhesives and other industries for its excellent properties. They have greater absorption in the UV and visible regions, and for coating systems containing pigments, they can initiate curing more effectively than other photoinitiators. Phosphine oxide photoinitiators have little yellowing after curing and under long-term light radiation, so they can be used in situations where yellowing is more stringent, such as: white, light-colored inks and coatings. In addition, acylphosphine oxide has a bleaching effect on light, and rays can penetrate the coating, which is conducive to the thorough curing of the thick film. Three novel phthalylin oxide photoinitiators, photoinitiator 819, photoinitiator 1800 and photoinitiator 1700, were introduced experimentally. Their structure and mechanism of photodecomposition were investigated by UV-visible spectrophotometry. These three highly effective photoinitiators can be used to synthesize polyacrylate-acrylic acid superabsorbent resin by ultraviolet (UV) photopolymerization. The effects of exposure time and the content of photoinitiators on the absorbent property of resin are compared comprehensively. The results showed that the activity of photoinitiator 819 was the highest, the polymerization of lmin system was basically complete and the monomer content was only 2.55%. In the early stage of the reaction, due to the high activity of photoinitiator 819, the polymerization products are mainly linear polymers with small molecular weight and low crosslinking rate. Only after 20min exposure can 83% crosslinking rate of water-absorbent polymers be obtained.

In addition, photoinitiator 819 can also be used for colored UV curable plastic coating, UV coating because of its excellent performance and efficient production has been widely used in a variety of electronic, home appliance products on the plastic shell, but the UV coating coating after the deep curing is not good, resulting in poor coating tight, and UV resin on the pigment dispersion of poor arrangement, seriously affecting the appearance of the coating film. Therefore, the traditional construction process is to paint solvent-based colored primer first, and then paint UV varnish after baking to improve the various physical properties of the paint film surface. The preparation method of colored UV curable plastic coating is carried out under the condition of room temperature shading and includes the following steps:

1) Photoinitiator 184, photoinitiator TPO and photoinitiator 819 are dissolved in an environmentally friendly solvent to obtain a photoinitiator solution for use;

2) Add the six-official aliphatic polyurethane acrylic resin, four-official aliphatic polyurethane acrylic resin and two-official aliphatic polyurethane acrylic resin into the mixing tank and stir for 8-15 minutes;

3) In the aliphatic polyurethane acrylic resin of step 2, add adhesion enhancer, wetting leveling agent and anti-settling agent while stirring, and stir for 8-15 minutes after adding;

4) In the material of step 3), add the photoinitiator solution of step 1) while stirring, and stir for 8-15 minutes;

5) Under agitation, add pigment paste to the material in step 4 for toning, and then filter to obtain the colored UV-curable plastic coating of the invention.

【 Reference 】

[1] http://baike.molbase.cn/cidian/78383

[2] Kim Yang Ji. Image Technology, 2011 (3): 8-18. [3] Zhu Junfei, Gong Ling, Fan Bin, et al. Research status and progress of photoinitiators [J]. Coating Industry, 2010, 40(5): 74-79. (in Chinese)

[4] Ruan Wei-Qing, Qiao Jin-Liang, Huang Yu-li, et al. Application of acylphosphine oxide photoinitiator in the synthesis of highly absorbent resin by UV photopolymerization [J]. Journal of Radiation Research and Technology, 2004, 22(4): 213-218.

[5] Fang Bo; Zhong Weishan; Li Guojun; Zhang Yu-Guo. Colored UV curable plastic coatings and preparation method thereof. CN201510309480.4, Application date 2015-06-09